- Our Services and Nanomedicines

- Our Services

-

Payloads and API

Explore our diverse range of payloads and APIs tailored for nanoparticle formulations.

-

Building Blocks

Discover our comprehensive suite of custom building blocks essential for personalized nanomedicine solutions.

-

Nanomedicine Development

Learn about our expertise in technology transfer, process development, and scale-up for innovative nanomedicines.

-

Nanomedicine Manufacturing

Explore our state-of-the-art facilities and scalable manufacturing solutions for nanoparticle-based products.

-

Fill & Finish and Clinical Supply

Navigate through our specialized services for aseptic fill-finish, clinical packaging, and supply chain logistics.

-

Regulatory and Bioanalysis

Gain insights into our strategic regulatory support and precise bioanalysis services for regulatory compliance.

-

- Nanomedicines

-

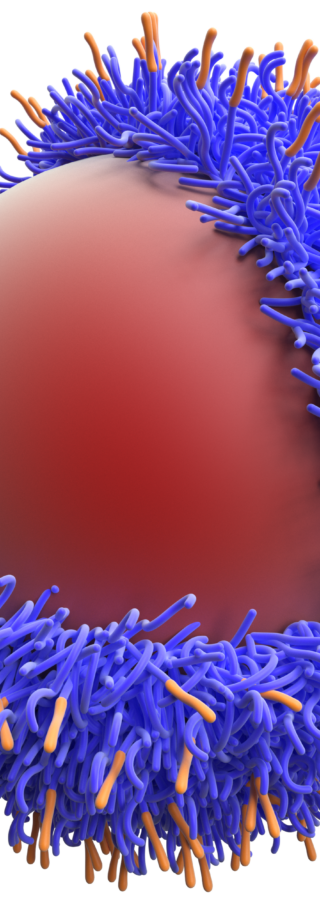

Lipid-based Nanoparticles

Explore the versatility of lipid-based nanoparticles for targeted drug delivery and therapeutic interventions.

-

Polymeric Nanoparticles

Learn about the advanced capabilities of polymeric nanoparticles in precision drug delivery and therapeutic applications.

-

Metal Nanoparticles

Discover the unique properties and applications of metal-based nanoparticles in nanomedicine and biomedical research.

-

- Our Services

- Resources

- Why choose Ardena?

- Why choose Ardena?

-

Our experience

Benefit from our extensive experience in nanomedicine development and manufacturing, spanning diverse therapeutic areas and applications.

-

Our integrated services

Take advantage of our seamless integration of services, providing end-to-end solutions for your nanomedicine projects.

-

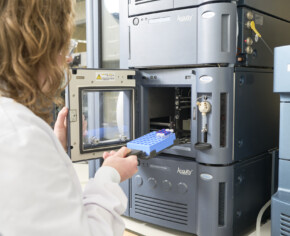

Our infrastructure

Utilize our state-of-the-art facilities and cutting-edge technology to ensure the quality and scalability of your nanomedicine production

-

- Why choose Ardena?

- About us

- About Ardena Nanomedicines

-

About Ardena Nanomedicines

Learn more about our company’s mission, values, and commitment to advancing nanomedicine technologies.

-

Our nanomedicine facility

Explore our state-of-the-art facility dedicated to nanomedicine research, development, and manufacturing, equipped with cutting-edge technology and adhering to strict quality standards.

-

Working at Ardena Nanomedicines

Discover opportunities to join our team and contribute to groundbreaking advancements in nanomedicine. Learn about our culture, benefits, and career opportunities.

-

- About Ardena Nanomedicines

- Contact